Invisible Influencer: Exploring Yeast’s Role in Irish Whiskey’s Complexity

Irish whiskey, known for its smooth, complex flavor profile, is a beverage that has captured the hearts of connoisseurs and casual drinkers alike. But behind every sip is an unseen artisan – yeast. This microscopic fungus plays a pivotal role in whiskey making, a role often overshadowed by its more tangible counterparts like barley and water. In “The Unseen Artisan: Exploring the Role of Yeast in Crafting Irish Whiskey,” we delve into the world of yeast, uncovering its critical function in the fermentation process and its profound influence on the final product.

Yeast is not just a component; it’s a catalyst that sparks the magical transformation from simple ingredients to a rich, flavorful spirit. This article aims to shine a light on this often-underappreciated player in whiskey production. From the science of fermentation to the impact of different yeast strains on flavor profiles, we explore how yeast has shaped the identity of Irish whiskey throughout history and continues to be at the forefront of innovation in the whiskey industry. Join us on a journey to understand and appreciate the subtle yet significant role of yeast in the art of whiskey making.

Introduction to Yeast in Whiskey Making

Yeast, though microscopic, plays a gargantuan role in whiskey making, especially in the revered realms of Irish whiskey. This segment delves into the intricate world of yeast and its indispensable role in the production of whiskey, revealing why it is indeed the unsung hero of the distillery.

The Essential Role of Yeast: Yeast is the cornerstone of whiskey production. Its primary job is to convert the sugars present in the mash (a mixture of water and cereal grains) into alcohol and carbon dioxide through fermentation. This process is the heartbeat of whiskey making, turning a basic, sweet liquid into a complex alcoholic beverage.

Types of Yeast Used in Whiskey Making: Distillers choose yeast strains based on the desired flavor profile. In Irish whiskey production, yeast strains are often selected for their ability to produce a light, fruity, and smooth spirit. These strains can impart subtle hints of apple, pear, or even citrus, contributing significantly to the whiskey’s final taste.

Yeast’s Contribution to Flavor: Beyond alcohol production, yeast strains play a crucial role in developing the whiskey’s flavor. During fermentation, yeast produces a range of congeners (by-products) like esters, alcohols, and acids, which are vital in shaping the whiskey’s character. The art of whiskey making involves balancing these congeners to achieve the desired flavor profile.

The Fermentation Process: In Irish whiskey making, the fermentation process typically lasts between 48 to 96 hours. This duration is crucial as it allows the yeast to not only convert sugars into alcohol but also to develop the right amount of congeners that contribute to the whiskey’s flavor. The temperature and pH of the fermentation environment are carefully controlled to optimize yeast activity.

Sustainability and Innovation in Yeast Cultivation: Distilleries are increasingly focusing on sustainability and innovation in yeast cultivation. Advances in biotechnology are enabling the development of yeast strains that can enhance flavors, increase alcohol yields, and even reduce the environmental impact of production. Some distilleries are experimenting with local wild yeasts, bringing unique regional characteristics to their whiskey.

In summary, yeast is a vital component in whiskey production, much more than a mere ingredient. It’s a living organism that not only initiates the fermentation process but also significantly influences the final flavor profile of Irish whiskey. The selection of yeast strains, control of the fermentation process, and ongoing innovations in yeast cultivation reflect the art and science behind crafting the beloved Irish spirit.

The Science Behind Fermentation

At the heart of Irish whiskey production lies the science of fermentation, a process as ancient as it is complex. This section explores the intricate dance of biochemistry where yeast, the unsung artisan of whiskey making, plays the lead role.

The Biochemical Process: Fermentation is the biochemical process where yeast metabolically converts sugars into alcohol and carbon dioxide. In the context of whiskey making, this process begins once the yeast is added to the mash, a mixture of water and milled grains that have been cooked to release their sugars. Yeast cells feed on these sugars, primarily glucose, and under anaerobic conditions (lacking oxygen), they produce ethanol (alcohol) and carbon dioxide.

Yeast’s Role in Flavor Development: The influence of yeast extends beyond just alcohol production. During fermentation, yeast creates a symphony of flavor compounds, including esters, alcohols, and acids. These compounds are responsible for the fruity, spicy, and floral notes that are characteristic of many Irish whiskeys. For instance, the production of esters, organic compounds formed from acids and alcohols, can impart fruity and floral aromas, ranging from apple and pear to more exotic tropical notes.

The Art of Controlling Fermentation: Master distillers skillfully control the fermentation process to influence the final product. Factors such as the choice of yeast strain, fermentation time, temperature, and even the shape of the fermentation vessels can alter the profile of these flavor compounds. A longer fermentation, for example, often results in a richer, more complex flavor profile, as it allows for the development of more congeners (flavor compounds).

Fermentation Time and Its Effects: The typical fermentation time for Irish whiskey ranges from 48 to 96 hours. This duration is crucial; a shorter fermentation period may yield a lighter, less complex flavor, while a longer period allows for the development of deeper, richer notes. The art lies in striking the right balance to achieve the desired flavor profile.

Advancements in Fermentation Technology: The whiskey industry is witnessing innovations in fermentation technology. New developments in yeast strain selection and fermentation control are enabling distillers to experiment with novel flavor profiles. Some distilleries are even exploring the use of genetically modified yeasts to enhance certain flavors or increase alcohol yields, pushing the boundaries of traditional whiskey making.

In conclusion, the science behind fermentation is a cornerstone of Irish whiskey production. It’s a blend of age-old traditions and modern science, where yeast, though small, makes an enormous impact on the whiskey’s character. Understanding this process provides insight into how each bottle of Irish whiskey is not just a product of its ingredients but a testament to the intricate science of fermentation.

Yeast Strains and Flavor Profiles

The diversity of yeast strains used in whiskey production is a testament to the complexity and depth of flavors achievable in Irish whiskey. This section delves into the intricate relationship between yeast strains and the sensory profile of the final spirit.

Variety of Yeast Strains: The choice of yeast strain in whiskey making is critical. Each strain possesses unique characteristics that influence the final product’s flavor and aroma. Distillers often use Saccharomyces cerevisiae, a species known for its reliable fermentation and desirable flavor profiles. However, within this species, there are numerous strains, each offering a different spectrum of flavors and aromas.

Influence on Flavor and Aroma: Yeast contributes significantly to the whiskey’s sensory profile through the production of congeners during fermentation. These congeners, which include esters, higher alcohols, and organic acids, are responsible for a range of flavors and aromas. For example, esters often impart fruity and floral notes, while higher alcohols can add spiciness and complexity.

Tailoring the Whiskey Profile: Distillers select yeast strains that complement their desired whiskey profile. For instance, a strain that produces high levels of esters might be chosen for a whiskey with a pronounced fruity character. This level of control allows for the creation of a wide array of flavor profiles, from light and delicate to rich and robust.

Regional Yeast Strains and Terroir: Some distilleries are exploring the use of local, wild yeast strains, which can impart unique characteristics to the whiskey, akin to the concept of terroir in wine. These indigenous yeasts can bring distinct regional flavors, adding another layer of complexity and uniqueness to the whiskey.

Innovation in Yeast Development: The whiskey industry is witnessing innovation in yeast development. Distilleries are collaborating with scientific institutions to isolate and develop new yeast strains that can produce specific flavor profiles. This scientific approach allows for greater precision in flavor development, paving the way for new and exciting variations of Irish whiskey.

In summary, yeast strains play a pivotal role in defining the flavor and aroma profile of Irish whiskey. The careful selection and cultivation of these strains demonstrate the art and science that goes into every bottle, making yeast not just a component but a crucial ingredient in the whiskey-making process. Understanding the impact of yeast on flavor profiles underscores the depth of craftsmanship involved in producing Irish whiskey.

The Evolution of Yeast Use in Irish Whiskey

The use of yeast in whiskey production is a tale as old as the drink itself, woven into the fabric of Irish whiskey’s rich history. This segment traces the evolutionary journey of yeast use in whiskey making, highlighting key advancements and their impact on the industry.

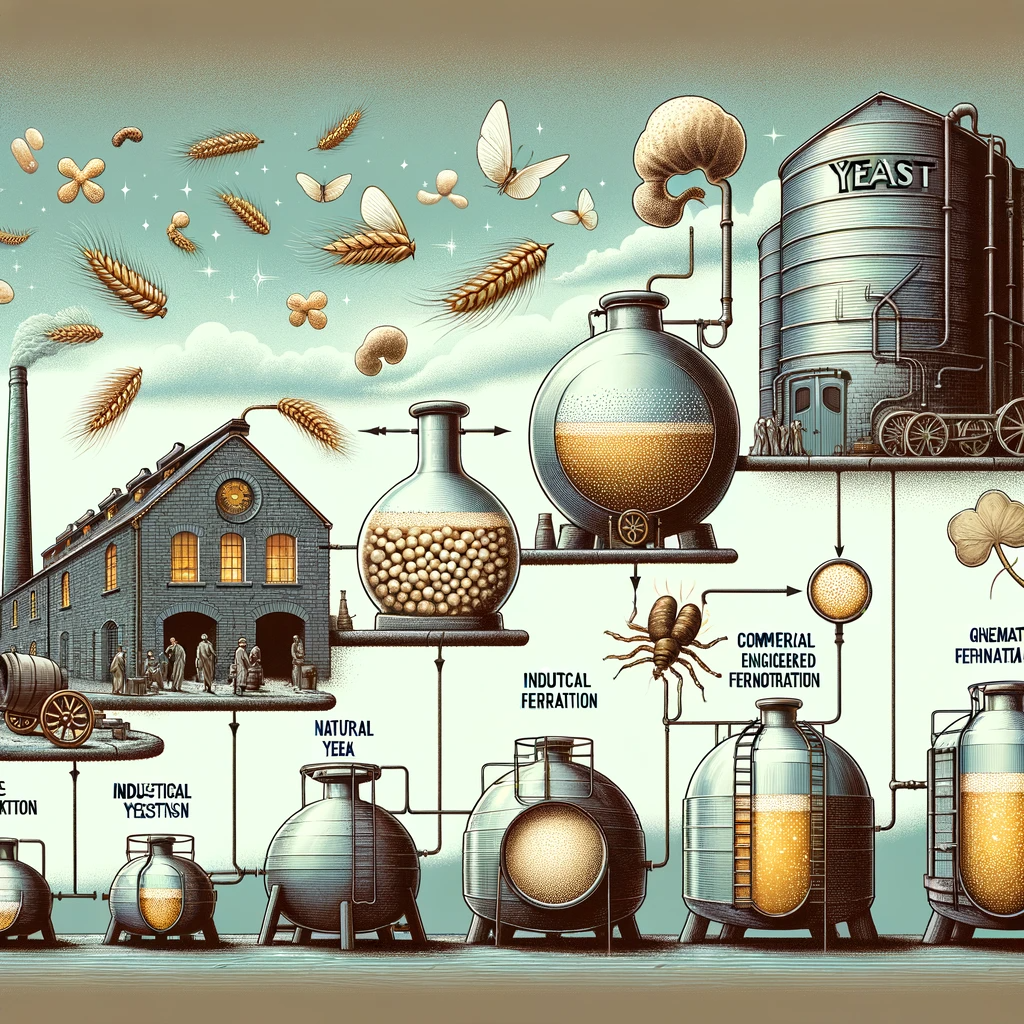

Early Use of Yeast in Whiskey Making: The story of yeast in Irish whiskey begins centuries ago. Originally, whiskey makers used whatever yeast was available, often relying on natural fermentation. This process involved airborne wild yeasts spontaneously fermenting the mash, resulting in a lack of consistency but a wealth of diverse flavors.

Development of Cultivated Yeast Strains: As understanding of fermentation grew, so did the cultivation of specific yeast strains. By selectively breeding yeast for desirable characteristics, distillers could achieve more consistent and predictable results. This practice marked a significant shift, allowing for greater control over the whiskey’s flavor profile.

Impact of Industrialization: The industrial revolution brought significant changes to the whiskey industry. Mass production and the development of commercial yeast strains led to more uniform flavors and higher production efficiencies. However, this also meant a reduction in the diversity of flavors that were characteristic of earlier, more artisanal methods.

Revival of Traditional Techniques: In recent years, there has been a resurgence in using traditional, non-commercial yeast strains. Many distillers are revisiting old methods, valuing the unique flavors and distinct characteristics that these strains impart. This revival is part of a broader trend in the whiskey industry towards craft and authenticity.

Innovation and Future Trends: Today, the industry is at a crossroads of tradition and innovation. Advanced techniques in yeast genetics offer new possibilities, from developing strains that are more resistant to climate change to those that can produce novel flavors. Distilleries are experimenting with genetically engineered yeasts to push the boundaries of flavor, aroma, and efficiency.

The evolution of yeast use in Irish whiskey is a testament to the industry’s adaptability and commitment to quality. From wild, spontaneous fermentation to advanced genetic engineering, the journey of yeast in whiskey making reflects both the preservation of tradition and the embrace of innovation. As the industry continues to evolve, the role of yeast remains central, continuously shaping the identity and diversity of Irish whiskey.

Modern Techniques and Innovations in Yeast Utilization

The whiskey industry, steeped in tradition, is also a field of constant innovation, particularly in the area of yeast utilization. This segment explores the contemporary techniques and future trends that are shaping the evolution of Irish whiskey.

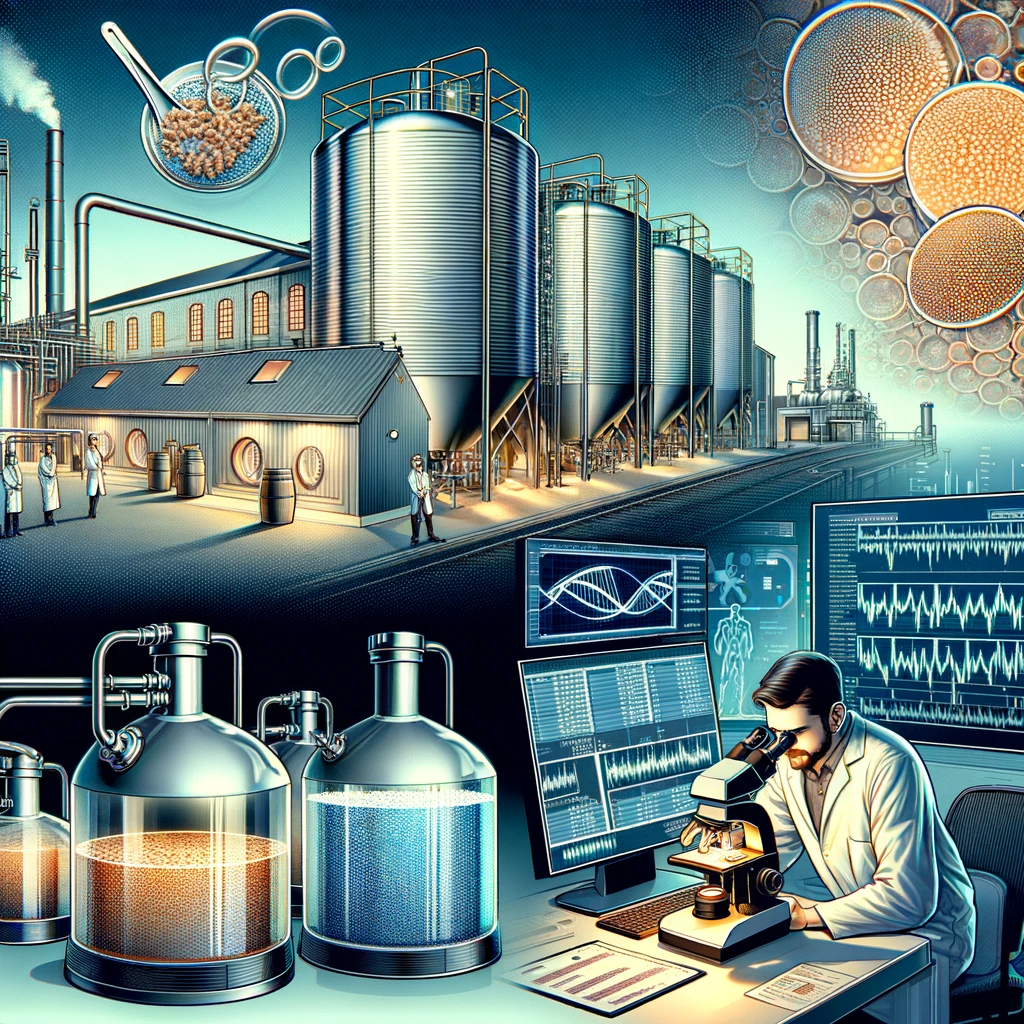

Advancements in Yeast Strain Development: One of the most significant areas of innovation is in the development of new yeast strains. Biotechnological advancements have enabled distillers to tailor yeast strains to specific flavor profiles. This precision in yeast cultivation allows for the creation of unique and complex flavors in whiskey, pushing the boundaries of traditional taste notes.

Genetic Modification and Flavor Enhancement: The exploration of genetically modified yeasts is a frontier in whiskey production. These yeasts can be engineered to enhance certain flavors or to increase alcohol yields. While the use of genetically modified organisms (GMOs) remains a topic of debate, their potential in crafting distinct whiskey flavors is undeniable.

Sustainability and Efficiency in Fermentation: Modern yeast technologies are also focusing on sustainability. Yeasts that can ferment more efficiently or at lower temperatures reduce energy consumption, making the whiskey production process more environmentally friendly. Additionally, certain yeast strains can be developed to better utilize alternative grains, reducing waste and expanding the range of sustainable raw materials.

Exploring Wild Yeasts and Local Terroir: A growing trend in the whiskey industry is the use of wild yeasts. This approach involves cultivating yeast strains indigenous to a region, capturing the essence of the local terroir in the whiskey. This method not only adds complexity to the flavor but also celebrates the uniqueness of the whiskey’s origin.

The Future of Yeast in Whiskey Making: Looking forward, we can expect continued innovation in yeast development. This could include the creation of yeasts that can withstand extreme fermentation conditions or those that can produce entirely new types of flavor compounds. The potential for yeast in whiskey production is vast, with ongoing research and experimentation poised to redefine the boundaries of whiskey flavor and production techniques.

In conclusion, modern techniques and innovations in yeast utilization are key drivers in the evolution of Irish whiskey. These advancements not only enhance the quality and variety of flavors but also contribute to sustainability and efficiency in production. As we look to the future, it is clear that yeast will continue to play a pivotal role in the whiskey industry, blending the art of traditional whiskey making with the science of modern innovation.

Conclusion

As we have explored in “The Unseen Artisan: Exploring the Role of Yeast in Crafting Irish Whiskey,” yeast is much more than a mere ingredient; it’s a fundamental artisan in the whiskey-making process. From the early days of natural fermentation to the cutting-edge genetic modifications of today, the evolution of yeast use in whiskey production reflects a blend of tradition and innovation.

The journey through different yeast strains and their impact on flavor profiles, the meticulous science behind fermentation, the historical progression of yeast cultivation, and the embrace of modern techniques underscore the intricate relationship between yeast and whiskey. This relationship is not just about the transformation of sugars into alcohol but about crafting the soul of the whiskey, its unique flavor, and character.

As whiskey enthusiasts and connoisseurs savor each drop of their beloved Irish whiskey, they are, in essence, tasting the results of centuries of evolution, science, and artistry. The world of Irish whiskey is a testament to the creativity and ingenuity of distillers who harness the natural powers of yeast to create a drink that is cherished worldwide.

In conclusion, yeast remains an indispensable, though often understated, component of whiskey production. Its role is pivotal in defining the essence of Irish whiskey, making every bottle a celebration of both its rich heritage and its innovative future.

Be First to Comment